Marine Electrical Cables

Our high-quality marine cables provide reliable underwater communication and power transmission, ensuring safety and durability in even the harshest marine environments.

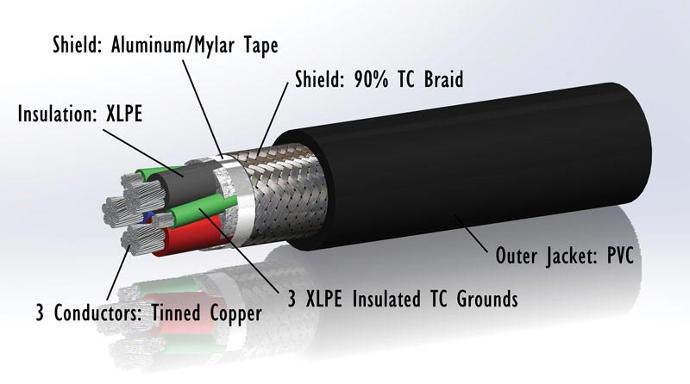

They come in different types, with varying conductors, insulations, and jackets, to suit specific needs. Common conductors include tinned copper or bare copper. Insulations include flame-retardant PVC, silicone rubber, rubber, polyvinyl chloride, and cross-linked polyethylene. Jackets are made of cross-linked polyolefin, silicon rubber, and polyvinyl chloride. Marine cables are available for a variety of shipyard applications.

We have an unmatched network of marine cable suppliers that allows us to offer marine cables from the top manufacturers at competitive prices on the market.

At OBMETRA, we sell different types of marine cables.

These include:

-

Marine Tinned Copper Wire, including duplex and triplex varieties. They are used for all types of marine applications and can also protect vehicles from water's impact.

-

Ancor Marine Grade Boat Cables

-

Marine Battery Cable that is flexible and used in batteries

-

Enhanced THOF 90°C Flexible 600V Ship-to-Shore Power Cable

-

Dual Booster Copper Conductor TPE Insulation Cable

When buying marine electrical cable, the following specifications should be considered:

1. Voltage rating: Ensure the cable is rated for the voltage it will be carrying.

2. Amperage rating: Ensure the cable can handle the amount of current it will be carrying.

3. Conductors: Consider the number of conductors needed for the application.

4. Stranding: The number of strands in the conductor can affect flexibility and durability.

5. Insulation material: Choose a material that can withstand the marine environment, such as PVC or cross-linked polyethylene.

6. Shielding: Consider if shielding is necessary to prevent electrical interference.

7. Size: Choose a cable with the appropriate size to meet the electrical load requirements.

8. Flexibility: Consider how flexible the cable needs to be for the application.

9. Chemical resistance: Ensure the cable can withstand exposure to salt water, fuel, and other chemicals.

10. Certification: Look for cables that are certified for use in the marine environment, such as by UL or the American Boat and Yacht Council (ABYC).

11. Standards: Ensure the cable meets relevant marine electrical standards, such as ABYC, ISO, or CE.

12. Temperature rating: Consider the operating temperature range of the cable and choose a cable that can withstand the temperatures it will be exposed to.

13. Cross-sectional area: Choose a cable with the appropriate cross-sectional area to meet the electrical load requirements

When buying marine electrical cable, the following specifications should be considered:

1. Voltage rating: Ensure the cable is rated for the voltage it will be carrying.

2. Amperage rating: Ensure the cable can handle the amount of current it will be carrying.

3. Conductors: Consider the number of conductors needed for the application.

4. Stranding: The number of strands in the conductor can affect flexibility and durability.

5. Insulation material: Choose a material that can withstand the marine environment, such as PVC or cross-linked polyethylene.

6. Shielding: Consider if shielding is necessary to prevent electrical interference.

7. Size: Choose a cable with the appropriate size to meet the electrical load requirements.

8. Flexibility: Consider how flexible the cable needs to be for the application.

9. Chemical resistance: Ensure the cable can withstand exposure to salt water, fuel, and other chemicals.

10. Certification: Look for cables that are certified for use in the marine environment, such as by UL or the American Boat and Yacht Council (ABYC).

11. Standards: Ensure the cable meets relevant marine electrical standards, such as ABYC, ISO, or CE.

12. Temperature rating: Consider the operating temperature range of the cable and choose a cable that can withstand the temperatures it will be exposed to.

13. Cross-sectional area: Choose a cable with the appropriate cross-sectional area to meet the electrical load requirements

What is Shipboard Cable?

The term “shipboard cable” covers a wide range of wire options. Different shipboard cables can be used for power, communication, control, lighting, electronics, instrumentation, and even other specialized applications.

No matter what the application or who the user is, the shipboard cable must be proven to be safe, effective, and reliable in any situation. Standards help manufacturers and end-users ensure that shipboard cable is designed to meet all product quality and safety requirements necessary for successful application on the seas.

Specifications

If you take a closer look at any of our

shipboard cable

specifications, you will see that the mil-spec numbers are followed by a series of letters. Each series represents a different version of that particular mil-spec cable. The letters let us know more about each one, including whether the cable is armored or unarmored, and whether or not the cable is watertight.

The following letters are associated with cable characteristics:

-

O = Unarmored

-

A = Armored

-

S = Shielded

-

W = Watertight

Specifications

If you take a closer look at any of our shipboard cable specifications, you will see that the mil-spec numbers are followed by a series of letters. Each series represents a different version of that particular mil-spec cable. The letters let us know more about each one, including whether the cable is armored or unarmored, and whether or not the cable is watertight.

The following letters are associated with cable characteristics:

-

O = Unarmored

-

A = Armored

-

S = Shielded

-

W = Watertight

Looking for these letters can help you decide which version of a certain mil-spec cable is right for your application.

Shipboard Cable for Your Business

Shipboard Cable for Power Applications

Shipboard power cables are essential equipment on a sea vessel ideal for transmitting and maintaining reliable signals. These are manufactured based on IEC 60092-353 / 354 standards. In challenging circumstances, shipboard power cables can reach and maintain high performance. Harsh conditions include:

- fire

- heat

- cold

- vibration

- humidity

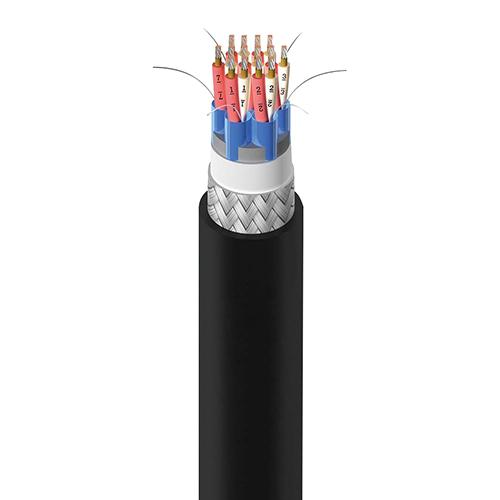

Shipboard Cable for Instrumentation

To maintain the safety of the ship, several instruments heavily rely on shipboard cables. These tools are essential for continuously informing the crew of the vessel’s condition. A large number of instruments are collaborating for the proper operation of watercraft including:

- Sensors

- trackers

- indicators

- recorders

- navigators

Shipboard Cable for Communication

To maintain the ship’s extensive network of communication devices, shipboard cables are needed. A well-organized communication system is necessary for a well-maintained watercraft. These systems are especially important for military and armored watercraft. It features:

- low toxicity constructions

- fire safety characteristics

- flexibility and abrasion resistance

- low smoke characteristics

Shipboard Cable for Control Systems

Honest shipboard cables are used in watercraft control systems. They precisely meet challenging conditions of the marine ecosystem in addition to a more extensive control system. Watercraft can be automated so they can run on their own thanks to controlling systems. These control systems make advantage of the shipboard wiring.

What Is the Application of Shipboard Cable?

There are a number of applications for a shipboard cable, which may include:

- Control systems

With the advancing technology, watercraft technology is also progressing by leaps and bounds.

In today’s world, most water vessels are becoming increasingly automated.

This automation requires a more comprehensive control system and a system that can work in the harsh conditions of the marine ecosystem.

Shipboard cables fit that criterion perfectly and are being used widely for laying the watercraft control system.

- Communication

A well-maintained water vessel requires a well-structured communication system.

These systems are especially requisite in armored/military water vessels.

These shipboard cables maintain an extensive network of communication devices within the vessel.

- Instrumentation:

For the proper working of watercraft, a great number of instruments are working in co-ordination such as the trackers, sensors, indicators, navigators as well as recorders.

These instruments are vital to update the crew of the vessel’s condition uninterrupted.

The shipboard cables are widely used in a number of these instruments to ensure the safety of the vessel.

- Power:

Shipboard cables are chiefly responsible for the transmission and maintenance of power to all the necessary devices and systems of a water vessel.